TM 10-4320-307-24

3-10

CASING AND COVER REPLACE(CONT).

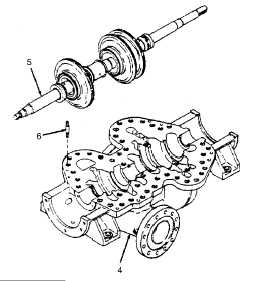

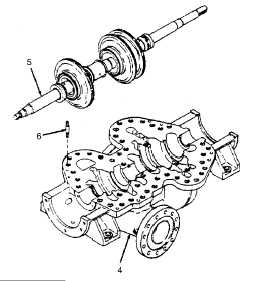

a.

Position

a

suitable

lifting

device

and

nonmarring slings over shaft assembly (5).

b.

Lift shaft assembly (5) from pump casing (4)

and carefully place onto blocks on a stable

work platform.

3.

Remove pump casing as follows:

Because the casing weighs more than

871 lbs (335 kg), a hoist will be required

to lift the casing to avoid personal injury.

a.

Remove 46 studs (6).

b.

Position a suitable lifting device and slings

over the pump casing (4) and carefully lift to

desired area.

CLEANING/INSPECTION/REPAIR:

Live steam used for cleaning shall not exceed 100 psi (690 kPa). During steam cleaning

operations, adequate ventilation, natural or forced, should be provided.

Do not direct live steam against skin.

Death or serious injury could occur if compressed air is directed against the skin. Do not use

compressed air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11

kgcm2) or less. When working with compressed air always use chip guards, eye protection, and

other personal protective equipment.

1.

Steam clean cover and casing assembly and dry with compressed air.

NOTE

Inspect the pump shaft assembly in accordance with paragraph 3-12.

2.

Inspect cover and casing for cracks, rust, corrosion, eroded or pitted areas, or other damage.

3.

Inspect wearing ring grooves in cover and casing for pitting, cuts, or distortion which could affect tight fit of wearing

rings.

4.

Inspect mounting surfaces and insure they are smooth and flat with no nicks or burrs.

NOTE

If repair requires replacement of the casing or cover, they must be procured as a matched set.

5.

Repair minor nicks or burrs on cover and casing and smooth out mounting surfaces with crocus abrasive cloth.

Clean and refinish outside surfaces. Remove only a minimum amount of surface material.

3-25