TM 10-4320-226-14

4.10.4. Cold Start Aid Nozzle Maintenance. (Not used on Model 350 PAWN)

This task covers:

4.10.4.1

Removal

4.10.4.2

installation

INITIAL SETUP

Tools

General Mechanic’s Tool Kit (appendix B, Section iii,

Item 1)

Equipment Conditions

General Safety Instructions

To prevent rolling or sliding, do not work on equipment

that is not securely stabilized.

Do not work on equipment without following standard

shop safety precautions.

Equipment shut down, refer to paragraph 2.5.2.

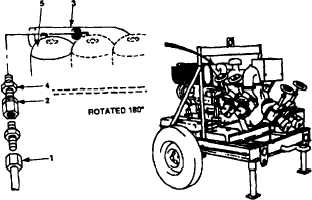

Figure 4-7. Starting Aid Nozzle Maintenance (Models 350 PAW and W-87012).

4.10.4.1

Removal.

To prevent roiling or sliding, do not work on equipment that is not securely stabilized.

Ensure both wheels are secure. Failure to obey these warnings could result in serious

personal injury.

a.

Disconnect hose (1, figure 4-7) from nozzle (2).

b.

Remove nozzle (2) from intake manifold (3).

4.10.4.2

installation.

a.

If arrow is not visible, hold nozzle as if being installed, and mark top flat of nozzle, so that ether would be injected

toward airflow.

b.

Thread jam nut (4) three quarters of the way on the nozzle (2).

c.

Thread nozzle (2) into intake manifold (3) approximately half way.

d.

Continue to thread until arrow on nozzle points towards number 1 cylinders (5).

e.

Tighten jam nut (4) to secure nozzle (2) and connect hose (1).

Change 2 4-20.4