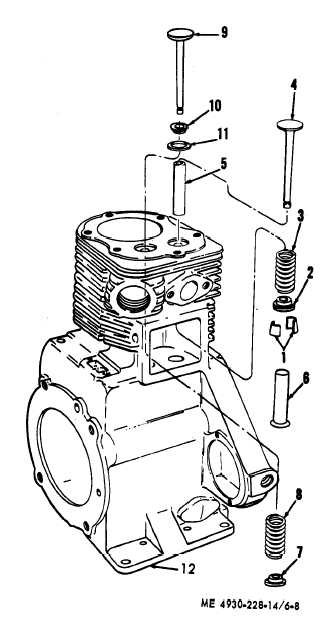

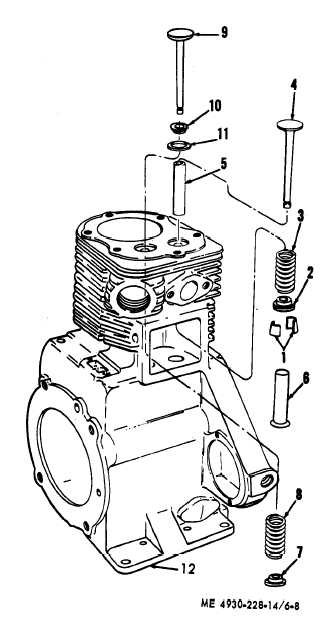

6-8

b . D i s a s s e m b l y . R e f e r t o f i g u r e 6 - 8 a nd

disassemble the valves, valve seats, guides, and

springs.

1 Lock (4)

2 Spring seat

3 Spring

4 Intake valve

5 Guide

6 Tappet (2)

7 Rotator

8 Spring

9 Exhaust valve

10 Cup (2)

11 Insert

12 Crankcase

Figure 6-8. Valves, exploded view.

c. Cleaning, Inspection, and Repair.

(1) Clean the valves with a wire brush to

remove all carbon deposits. Clean valve seats,

ports, and guides in cylinder block; clean top of

cylinder block. Wash springs with cleaning solvent

and dry thoroughly.

( 2 ) I n s p e c t v a l v e s f o r b u r n e d , p i t t e d , or

cracked faces: replace a burned, cracked, or deeply

pitted valve.

(3) Inspect valves springs for cracks or pitting.

Replace cracked or pitted springs.

(4) Inspect valve seat insert for looseness and

pitting. Replace a defective valve seat insert in the

following manner:

(a) Use a puller to remove the insert from

the exhaust valve opening.

( b ) C l e a n a l l c a r b o n o u t o f t h e i n s e rt

counterbore in the cylinder block and clean the

valve stem guide bore.

(c) Finish the counter bore in the cylinder

block to provide the correct bore-to-insert in-

terference. Chill the insert with dry ice and, using a

pilot driver, tap the insert into place with light

blows. Peen the insert to anchor in place.

(d) Reface the insert, if necessary, to make

its seat concentric with the valve. Check con-

centricity with a dial indicator.

(c) Lap valve in seat to form a gas-tight seat.

d. Regrinding Valves.

(1) Using a valve seat grinding tool, grind the

seats at a 45° angle and then grind the valve faces at

a 45° angle with a valve refacer grinder.

(2) Valves must be lapped with a suitable

lapping compound or they will leak within the first

few hours of operation because of improper seating.

(3) Clean valve seat and faces with cleaning

solvent and dry thoroughly.

(4) After lapping the valves, remove them

from the block and wash the valves and block with

cleaning solvent.

e . R e a s s e m b l y . R e f e r t o f i g u r e

6 - 8 a nd

reassemble valves.

f. Installation.

(1) Install valve inspection cover (para 6-8).

(2) Install cylinder head (para 6-7).

(3) Install carburetor (para 4-25).

(4) Install engine (para 6-5).

6-10. Engine Base and Oil Pump

a. Removal.

(1) Remove the engine (para 6-5).

(2) Refer to figure 6-9 and remove the engine

base and oil pump.

b . D i s a s s e m b l y . R e f e r t o f i g u r e 6 - 1 0 a nd

disassemble the engine base and oil pump.

c. Cleaning, Inspection, and Repair.

(1) Clean all parts with cleaning solvent and

dry thoroughly.