Table 3-2. Operator’s Troubleshooting-continued

MALFUCNTION

TEST OR INSPECTION

CORRECTIVE ACTION

7. PRODUCT DISCHARGE IS DIRTY

Step 1. Check for excessive differential pressure.

Service filter/separator if dirt is causing high pressure.

Step 2. Check to find loose filter element.

Seat filter element if loose.

Step 3. Check to find if inside of filter /separator is dirty.

Clean inside of filter separator if dirty.

Step 4. Check for ruptured filter elements.

Replace ruptured elements.

Section IV. FUEL TANK SCREEN, FUEL STRAINER, AND

FILTER / SEPARATOR MAINTENANCE PROCEDURES

3-7. General

This section contains the maintenance instructions

for the tank and pump unit that are applicable to

the operator.

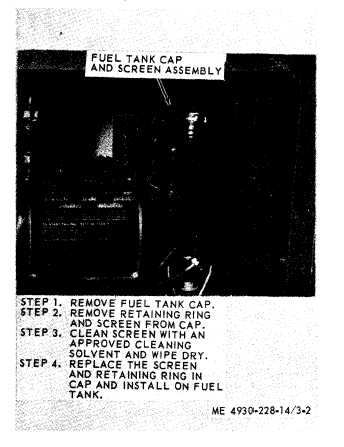

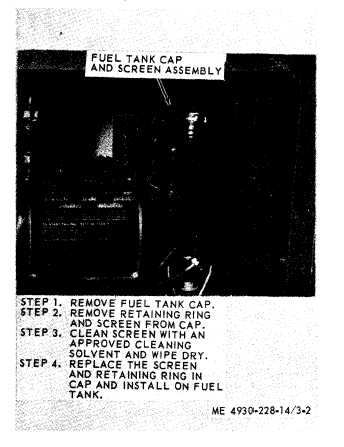

3-8. Fuel Tank Screen Service

Refer to figure 3-2 and service the fuel tank screen.

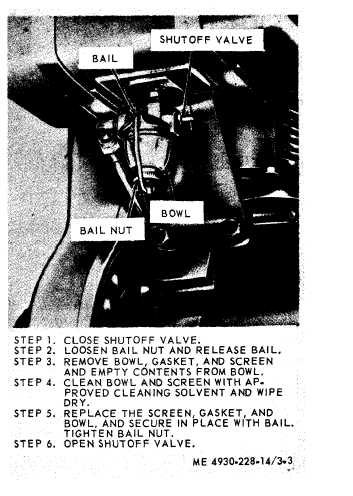

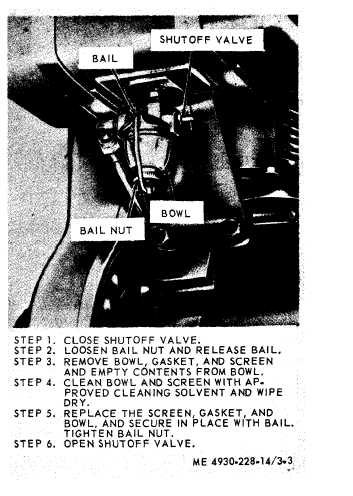

3-9. Fuel Strainer Service

Refer to figure 3-3 and service the fuel strainer.

Figure 3-3. Fuel strainer service.

Figure 3-2. Fuel tank screen service.

3-4