TM 5-4320-302-14

6-20. CRANKSHAFT ASSEMBLY (CONT)

Location/Item

Action

Remarks

30. Main bearing

Inspect and replace for excessive wear, over-

bracket

heating, distortion, cracking, high spots, or

other damage.

NOTE

If main bearing bracket is replaced, main bearing support

must also be replaced.

31. Main bearing

Inspect for excessive wear, overheating, distortion,

supports

cracking, or other damage. Measure bearing support

wall thickness, which should not be less than 0.1170

inch (2.973 mm). If measurement is less than tolerance

limit, replace main bearing supports with normal

or oversized wall thickness bearing support.

32. Main bearing

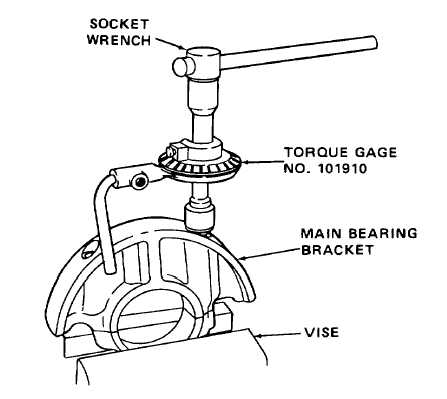

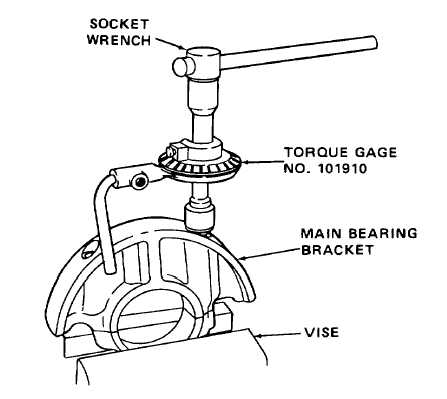

Assemble bearing bracket, clamping bush, washers,

bracket bore

and screws. Make sure matchmarks line up properly

and clamp in vise. Make sure threads and seat areas

are clean. Lightly lubricate them with MIL-L-2104

lubricating oil. Tighten screws alternately and evenly,

in small increments, to 22.13 ft lb (30 N.m) torque.

Using torque gage No. 101910, tighten screws two

additional times in increments of 30 degrees.

6-177