TM 5-4320-302-14

6-18. CRANKSHAFT ASSEMBLY (CONT)

Location/Item

Action

Remarks

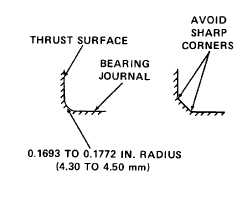

16. Crankpin and

All fillets must have a 0.1693 to 0.1772 inch

journals

(4.30 to 4.50 mm) radius between crank cheek

fillets

and crankpin or journal and must not have any

sharp grind marks. Fillet must blend smoothly

into crankpin or journal and crank cheek, and

must be free of scratches. Check radius with a

fillet gage and polish smooth any slight imper-

fections with P-C-458 crocus cloth wet with

VV-F-800 diesel fuel oil. If radius is too far out-

side specified limits, the crankshaft crankpins

and/or journals and crank cheeks must be re-

ground and the crankshaft replaced.

17. Crankpin and

Stone edges of all oil holes in crankpin and

bearing journal

journal surfaces with MIL-S-17243 surfacing

oil holes

stone to provide a smooth radius.

WARNING

Severe burns, illness, or death may result if personnel fail

to handle diesel fuel oil properly. Observe the following

precautions:

·

Do not inhale vapor.

·

Work in a well-ventilated area.

·

Do not use near open flame, sparks, or excessive heat.

18. Ground

Polish ground surfaces to an 8 to 12 RMS finish

surfaces

with P-C-458 crocus cloth wet with VV-F-800

diesel fuel oil.

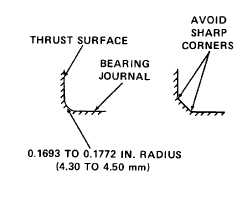

19. Crankshaft

Inspect. If slightly worn or grooved, smooth

thrust

out and polish surfaces with wet crocus cloth.

surfaces

Make sure to leave a 0.1693 to 0.1772 inch

(4.30 to 4.50 mm) radius on

crankshaft between each

thrust surface and bear-

ing journal or crankpin.

6-151