TM 5-4320-302-14

4-35.

ENGINE SHUTDOWN VALVE (CONT)

Location/Item

Action

Remarks

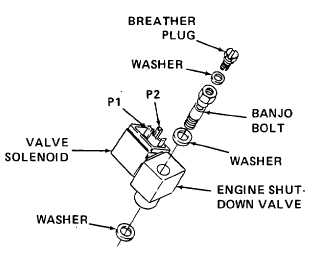

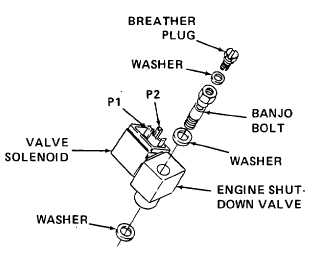

3.

Engine shut-

Remove breather plug, washer,

down valve

and banjo bolt from fuel in-

jection pump by rotating

counterclockwise. Remove

and discard washers.

TEST/INSPECTION

4.

Engine shut-

Electrically test operation of engine shutdown

down valve

valve and valve solenoid. Connect pin (P2) to

ground. Intermittently apply +12 vdc to pin 1

(P1). The valve should normally be open with

+12 volts applied to pin 1 (P1) but should

close when no voltage is applied to pin 1 (P1).

These signals simulate the engine fault sensi-

tive control signals from the control panel.

Test valve is open when an electrical signal

(+12 vdc) is applied to the valve solenoid pin

1 (P1), simulating the reset signal. If either

malfunction, replace engine shutdown valve

and solenoid.

5.

Engine shut-

Inspect valve, breather plug, and banjo bolt

down valve

for damage, rust, corrosion, or restrictions in

fuel flow. If damaged, severely rusted, or cor-

roded, replace valve. If valve needs to be ad-

justed, follow adjustment procedure below.

Inspect electrical contacts on both ends of

electrical connectors at engine shutdown valve.

Inspect wiring to and from control panel. For

connections at control panel, follow procedures

in paragraphs 4-15 and 4-16. If any electrical

problems or malfunctions exist, replace wiring

and/or connectors as necessary.

4-167