TM 5-4320-300-14

6-7. CYLINDER HEAD AND BLOCK (CONT)

Location/Item

Action

Remarks

CAUTION

Equipment damage could occur if bearing caps are not returned to their original

positions. Follow directions noted during disassembly.

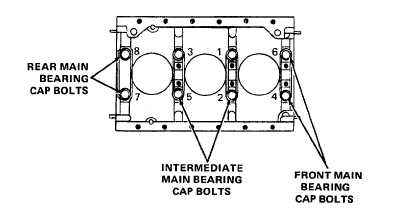

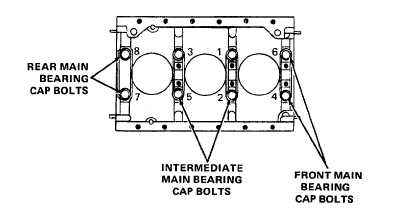

61. Bearing bore

Install main bearing caps. Torque front and

diameter

intermediate main bearing cap bolts to 120 to

130 ft lb (163 to 176 N•m), in an alternating

pattern as shown. Torque rear main bearing

cap bolts to 40 to 50 ft lb (54 to 68 N•m).

Check main bearing bores for proper diameter.

The specified bore diameter is 3.251 to 3.252

inches (82.575 to 82.60 mm). If the bores do

not fall within these limits, the cylinder block

must be replaced.

62. Bearing bore

Check bearing bore alinement by installing new

alinement

bearing shells, installing the crankshaft and bear-

ing caps, tightening the cap bolts to the specified

torque, and rotating the crankshaft by hand in

accordance with paragraph 6-11.

REPLACEMENT OF

CYLINDER BLOCK

END PLATE

63. Cylinder block

Replace end plate if seriously nicked, dented,

end plate

scratched, or scored. Replace end plate plug

nuts having cracks or damaged threads. Re-

place end plate if seriously warped.

6-44