TM 5-4320-300-14

6-7. CYLINDER HEAD AND BLOCK (CONT)

Location/Item

Action

Remarks

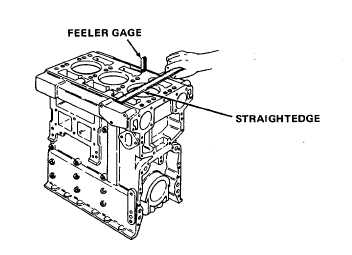

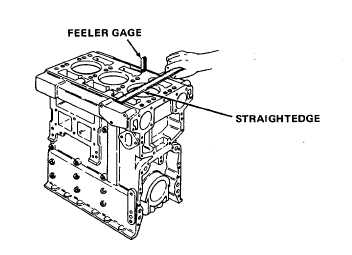

59. Cylinder block

Check the top of block for flatness with an

surface

accurate straightedge and a feeler gage. The

top surface must not vary more than 0.003

inch (0.0762 mm) transversely and not over

0.006 inch (0.1524 mm) longitudinally.

60. Cylinder liner

Wash in clean VV-F-800 diesel fuel and dry

counterbores

with compressed air. Check counterbore

depth. The depth must be 0.300 to 0.302

inch (7.620 to 7.671 mm) and must not vary

more than 0.0015 inch (0.0381 mm) through-

out the entire circumference. The counter-

bored surfaces must be smooth and square

with the cylinder bore within 0.001 inch

(0.0254 mm) total indicator reading. There

must not be over 0.001 (0.0254 mm) differ-

ence between any two adjacent cylinder

counterbores, when measured along the cyl-

inder longitudinal centerline of the cylinder

block.

6-43