TM 5-4320-300-14

6-6. OIL PUMP (CONT)

Location/item

Action

Remarks

14. Screen

Inspect seal surface for damage. Inspect screening

for tears or obstructions. Clean to remove obstruc-

tions. Replace if damaged.

15. Mounting

Inspect bolts for damaged threads. Replace if

bolts and damaged. Inspect lockwashers. Replace if damaged

lockwashers or missing.

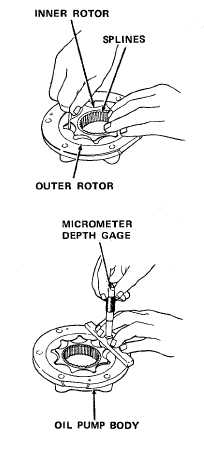

16. Pump rotors,

Inspect the lobes and faces

body, and of pump rotors for scratches

cover plate or burrs and the surfaces of

pump body and cover plate

for scoring. Slight scratches

or score marks may be re-

moved with P-C-458 crocus

cloth.

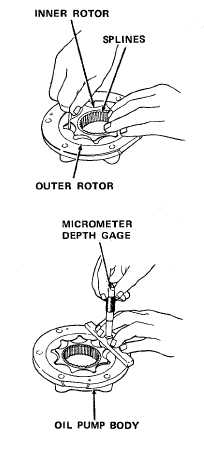

Measure the clearance between

inner and outer rotors at each

lobe. The clearance should not be

less than 0.004 inch (0.1016 mm)

or more than 0.011 inch (0.279

mm). Measure the clearance from

the face of pump body to the

side of inner and outer rotor with

a micrometer depth gage. The

clearance should be not less than

0.001 inch (0.0254 mm) or more

than 0.0035 inch (0.0889 mm).

NOTE

Wear on pump rotors may be kept to a minimum by using clean oil. If dirt and sludge are allowed

to accumulate in the lubricating system, excessive rotor wear may occur in a comparatively short

period of time.

17. Inner rotor

Inspect for excessive wear.

and oil pump

drive gear

splines

6-20