TM 5-4320-218-15

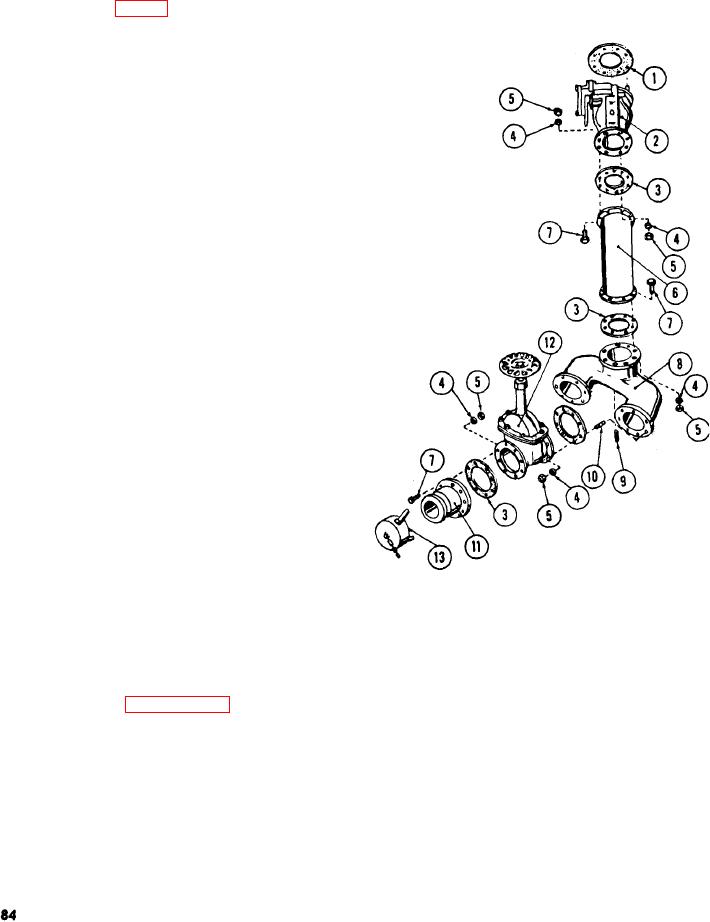

Section XVIII. PUMP DISCHARGE MANIFOLD

The purpose of the pump discharge mani-

fold (8) is to provide a multiple connection for

discharge hoses. Two 4-inch gate valves (12)

are mounted on the manifold. Each gate valve

is equipped with a flange adapter (11) and

dust cap (13).

135. Pump Discharge Manifold

Maintenance and Repair

a. Removal and disassembly.

(1) Remove the dust caps (13).

(2) Remove the nuts (5) and lockwashers

(4) and cap screws (7) securing the

adapters to the gate valves (12), Re-

move the adapters and gaskets (3 and

11).

(3) Remove the nuts (5) and lockwashers

(4) securing the gate valves (12) to

the discharge manifold (8). Remove

the gate valves and gaskets.

(4) Remove the nuts (5) and lockwashers

(4) and remove the discharge mani-

fold (8) from discharge elbow (6).

b. Cleaning, inspection, and repair.

(1) Clean all parts with an approved

cleaning solvent and dry thoroughly.

(2) Discard all gaskets removed and use

new gaskets for reassembly,

(3) Inspect all hardware for stripped

threads and wear. Replace any part

necessary,

(4) Inspect the manifold for cracks and

holes. Inspect the manifold flanges

for warpage and cracks, Replace a de-

1

Gasket and valve seat

fective manifold.

2

Valve assembly check

(5) Refer to paragraph 129 for mainte-

3

Gasket

4

nance and repair of the gate valves.

Lockwasher

5

Hex nut

(6) Inspect the dust caps for broken

6

Discharge elbow

chains, worn cam arms, and cam arm

7

Cap screw

pins. Replace worn arms and pins.

8

Discharge manifold

9

Pipe plug

(7) Inspect the extension pipes for cracks

stud

10

and damaged threads. Replace a dam-

11

Flange adapter

aged pipe.

12

Gate valve assembly

13

Dust cap

c. Reassembly and installation. Reverse the

procedure outlined in a above.

Figure 38. Pump discharge manifold, exploded view.