TM 5-4320-218-15

(11) Install the spark plug in No. 1 cyl-

(4) Inspect the valves for burned, pitted,

inder.

or cracked faces; replace a burned,

c. Removal.

cracked, or deeply pitted valve.

(1) Remove the governor (par. 57c).

(5) Inspect the valve springs for brakes

and wear. Compare with a new

(2) Remove the cylinder heads (par.

spring and replace if weak or dam-

101a).

aged.

(3) Remove the valve covers (par.

(6) Inspect the valve seat inserts for loose-

102b).

ness and excessive wear,

(4) Use a valve spring compressor and

(7) Inspect and replace all unserivceable

compress the valve spring. Remove

parts.

the pair of valve spring seat locks, the

e. Valve and valve seat refacing.

valve stem roto cap, and valve spring

(1) Reface valves and valve seats only

seat. Remove the spring compressor,

when there is evidence of warping or

lift out the valve, and remove the

deep pits. A good method of detect-

valve spring.

ing warping is to check each valve

stem in a valve face grinder, and slow-

ly rotate the valve while the grinding

wheel is brought near the rotating

valve face.

d. Cleaning and inspection.

(2) Using a valve face grinder, reface the

(1) Clean the valves on a wire wheel brush

valves to an angle of 45 degrees. Re-

to remove carbon from the valve face

place any valve that measures less

and gum deposits from the stems.

than 0.0625 inch from the top of head

Wash the springs with an approved

to the edge of the refaced outer cir-

cleaning solvent, and dry thoroughly.

cle.

(2) Use a rifle brush to clean out the

(3) Install a pilot in the valve stem bore

valve guides in the cylinder block;

of the cylinder block. Set the stone

blow out with compressed air.

on the valve reseating outfit to the

(3) Clean the valve seat inserts and top

angle of 45 degrees and dress the

of the cylinder block.

stone with the dresser. Place the

grinder and stone assembly over the

pilot in the valve stem bore, and grind

just enough to make a smooth seat.

f. Valve grinding procedure.

(1) Remove all traces of cabon from the

face of the cylinder block.

(2) Lightly coat the entire valve seat

with a good quality water-soluble

valve grinding compound. Slip a

light lifting spring over the valve

stem, and lubricate the stem. Drop

the valve into its original place in the

cylinder block. The lifting spring

should barely hold the valve off its

seat. Set the grinding tool on the

valve head, and press down until the

valve is seated. Turn the valve one-

quarter turn, first in one direction.

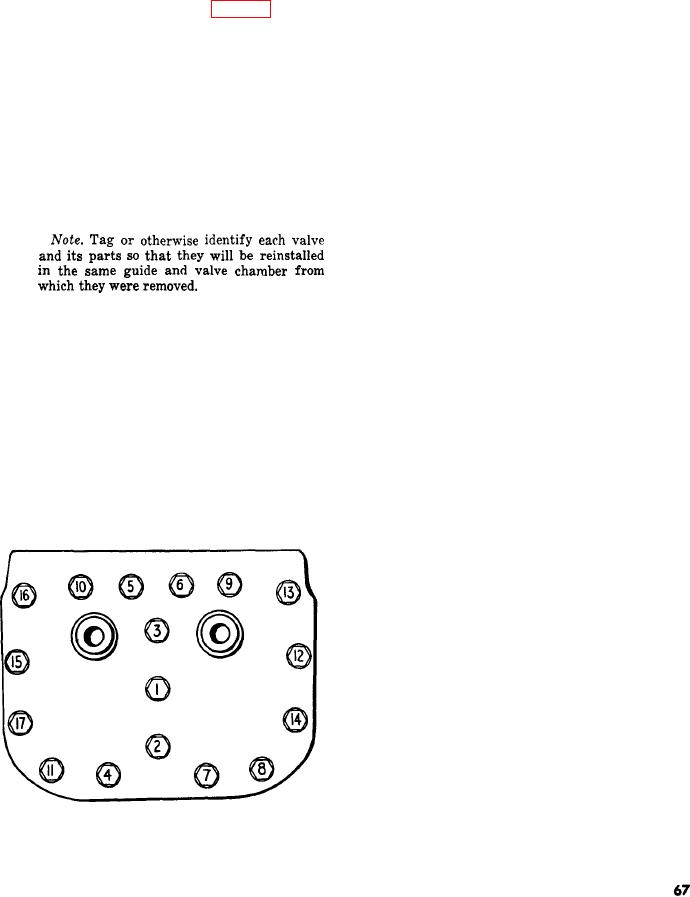

Figure 31. Cylinder head tightening sequence.

then in the other. Do this three or