4.4.21 Engine Block Maintenance, Unit 609-A.

(Continued)

Irregularities in cylinder bore may result in

h.

Check cylinder bore out-of-round and taper.

0.003 inches (0.076 mm).

Taper must not be

in each cylinder bore.

galling and seizing of

Out-of-round must not

more than 0.002 inches

p i s t o n s .

exceed

(0.051 mm)

i .

Using accurate straight edge and a feeler gage, check top of engine block (1)

f o r f l a t n e s s.

Top of surface may not vary-more than 0.005 inches (0.127 mm)

on width or length.

Out-of-flatness should vary gradually and uniformly from

end to end and side to side.

j .

Replace any damaged, loose, or broken dowel pin (18).

k.

Refer to paragraph 2.11.2 and replace any damaged, loose, or broken studs

(17).

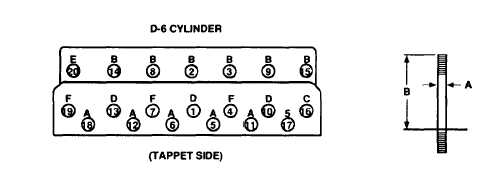

Figure 4-39.

Engine

Install end oil passage studs so

center line of rocker arm shaft.

Block Stud Location, Model 609-A.

that oil holes are within a 40° angle with

1.

If necessary, add adhesive in hole and install new stud(s) (17) in engine

block (1) to dimensions indicated in Table 4-17.

(Refer to Figure 4-39.)

Table 4-17.

Stud Dimensions.

6 Cylinder

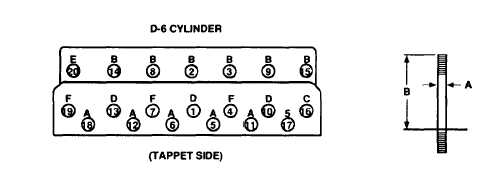

Stud

A-Diameter

B-Height

A

0.562 inches (14.275 mm)

4.620 inches (117.348 mm)

B

0.625 inches (15.875 mm)

4.680 inches (118.872 mm)

C - Oil Supply

0.625 inches (15.875 mm)

6.620 inches (168.148 mm)

D - Cover

0.625 inches (15.875 mm)

7.430 inches (188.722 mm)

E - Lift

0.625 inches (15.875 mm)

5.810 inches (147.574 mm)

F

0.625 inches (15.875 mm)

6.620 inches (168.148 mm)

m.

Check main bearing bores of engine block (Figure 4-38, 1) as follows:

4-78

TM 10-4320-344-24