TM 10-4320-321-13&P

FORM 5S2583

MODELS 2P121 THRU 2P128 & WP373 THRU 2P380

01615

Maintenance (Continued)

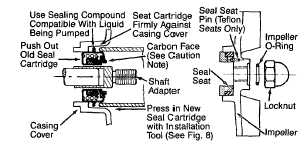

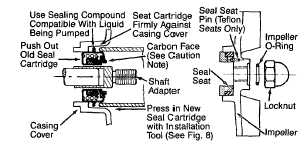

Figure 7. Mechanical Seal Replacement (Teflon Seal

Shown)

3.

Unscrew impeller (Ref. No. 14) from the shaft

adapter. Remove the impeller O-ring (Ref. No. 15)

and clear all sediment from impeller. Inspect the

impeller O-ring, replace if deeply scarred or worn.

NOTE: DO NOT remove or adjust shaft adapter (Ref. No. 3).

4.

Pry seal seat (Ref. No. 12) from recess of impeller.

Use caution so as not to damage or remove seal seat

pin (Ref. No. 13) on Teflon seal equipped units.

5.

Remove the adapter and casing cover (Ref. Nos. 5 &

8) by unthreading four fasteners (Ref. Nos. 7 & 22; two

of each).

6.

Press seal cartridge (Ref. No. 11) from the rear of the

casing cover.

7.

Clean casing cover and impeller seal recesses and

shaft adapter. Make certain all surfaces are perfectly

clean before installing new seal parts.

CAUTION: Handle seal parts with extreme caution and keep them

clean. Do not touch seal faces (either ceramic or carbon) with your

hands. Do not apply lubricants on seal faces. This could cause a leak

or premature seal failure.

8.

Apply a light coat of sealing compound to new seal

cartridge (See Figure 7) and press it into the casing

cover recess using the proper size tube or installation

tool (See Figure 8). DO NOT press on carbon face or

top of metal cup of the seal cartridge. Install using

flange only.

9.

Slide the assembled adapter and casing cover (Ref.

Nos. 5 & 8) onto motor mounting face. Fasten with

four fasteners (Ref. Nos. 7 & 22; two of each), making

sure that the mounting foot (Ref. No. 23) is in place.

10. Press new seal seat (Ref. No. 12) squarely into the

impeller recess. Align slot in the seal seat with seal

seat pin (Ref. No. 13) on Teflon equipped units. Avoid

scratching the ceramic surface.

NOTE: Use a soft, clean piece of cloth on seal seat face when

installing to prevent marring.

11. Screw the impeller back in place, tightening until it is

firmly seated.

12. Install the impeller 0-ring (Ref. No. 15) and install and

tighten impeller locknut (Ref. No. 16).

13. Reinstall O-ring seal (Ref. No. 10) on casing cover

rabbet. Remount casing (Ref. No. 17) with six

fasteners (Ref. No. 9).

14. If 3/16" hex key (Allen wrench) was inserted into the

shaft adapter clamp screw to prevent shaft rotation,

remove it. Pump may now be returned to service.

NOTE: Always flush pump thoroughly before use so as not to

contaminate liquid being pumped.

IMPELLER CLEARANCE ADJUSTMENT

When installing replacement motor, shaft adapter

(Ref. No. 3), adapter (Ref. No. 5), casing cover

(Ref. No. 8), impeller (Ref. No. 14) or casing (Ref.

No. 17), it may be necessary to adjust the

clearance between the impeller and casing faces.

NOTE: A proper running clearance is less than 0.021".

CAUTION: If the impeller (Ref. No. 14) is replaced, the seal

assembly should also be replaced as the seal is usually

damaged in disassembly. Also replace Teflon washer (Ref.

No. 15).

1.

After the replacement components have been

installed, reassemble the pump as described

under "Mechanical Seal Replacement". DO

NOT remount pump casing (Ref. No. 17) at this

time.

2.

Loosen lock screws (Ref. No. 1) in shaft

adapter clamp (Ref. No. 2) as the impeller will

move in and out freely. Leave loose but do not

remove the assembly from the motor shaft

(screws

are

accessible

through

adapter

openings).

3.

Stand the pump up on motor end if possible

and place a 0.020" feeler gauge in the face of

the impeller (if feeler gauge is not available,

use five to six thicknesses of newspaper. Make

sure impeller and casing are absolutely dry and

clean). With pump still on end, remount the

casing (Ref. No. 17) tightening fasteners (Ref.

No. 9) evenly.

4.

Make certain the full width of shaft adapter

clamp (Ref. No. 2) is in place on shaft adapter

and the split in the shaft adapter (Ref. No. 3) is

aligned with the part between the clamp halves

and retighten lock screws (Ref. No. 1).

5.

Unthread fasteners (Ref. No. 9) and remove

casing (Ref. No. 17). Remove feeler gauge (or

newspaper pieces). Then mount casing making

certain all fasteners are tight.

NOTE: Make certain that O-ring seal (Ref. No. 10) is in place.

6.

Check shaft to make sure it turns freely (turn

shaft with shaft adapter clamp). This procedure

should insure the proper running clearance and

will deliver maximum performance from the

pump.

NOTE: If shaft will not turn, remove casing (Ref. No. 17) and

repeat above procedure beginning with step 2.

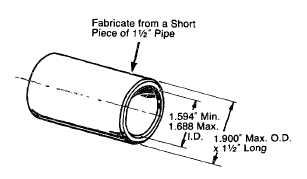

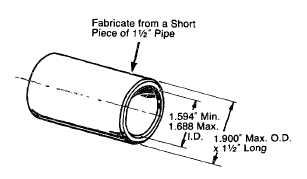

Figure 8 - Seal Installation Tool

-7-