TM 10-4320-307-24

2-22

TANK ASSEMBLY REPAIR/REPLACE (CONT).

CLEANING/INSPECTION/REPAIR:

Dry cleaning solvent is potentially dangerous. Avoid repeated and

prolonged breathing of vapors and skin contact with the liquid. Do not use

near open flame, arcing equipment, or other ignition source. Always wear

eye protection and protective clothing.

Death or serious injury could occur if compressed air is directed against the

skin. Do not use compressed air for cleaning or drying unless the pressure

Is/has been reduced to 30 psi (2.11 kgcm2) or less. When working with

compressed air always use chip guards, eye protection, and other personal

protective equipment.

1.

Clean outside of fuel tank assembly with dry cleaning solvent. Dry with compressed air.

2.

Inspect fuel tank for dents, rust, corrosion, leaks, or other damage.

3.

Remove minor corroded, dented, or chipped areas using crocus abrasive cloth. Clean and refinish surfaces.

4.

Inspect mounting brackets for broken welds. If any welds are found cracked, notify direct support maintenance.

5.

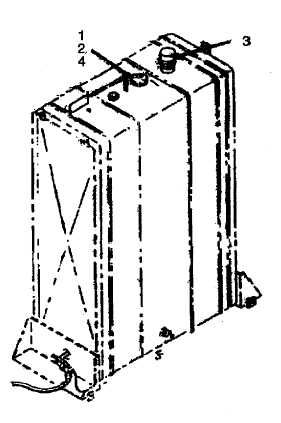

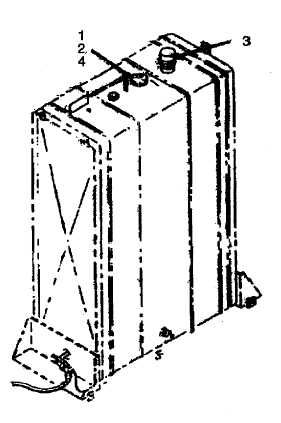

Remove fuel tank cap (1) and check that gasket (2) is present and in good condition. Replace as necessary.

6.

Inspect fuel level gauge (3) for damage. Replace if necessary.

7.

Inspect fuel tank cap vent valve (4) is open and free from any debris.

8.

If further maintenance is required, notify direct support maintenance.

2-52