TM 10-4320-307-24

4-11

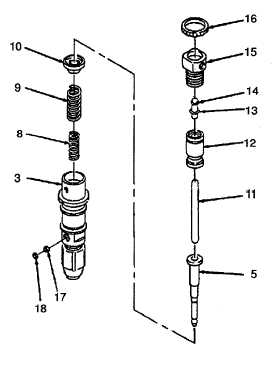

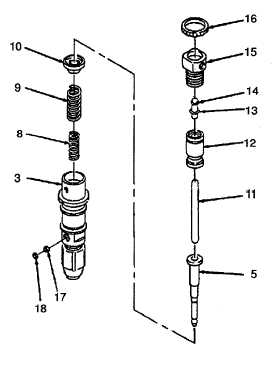

INJECTOR REPAIR(CONT).

8.

To check plunger alignment by hand proceed as follows:

Death or serious injury could occur if diesel fuel oil is not handled

carefully. Use in a well-ventilated area away from open flame, arcing

equipment, ignition sources, heaters, or excessive heat. Always store fuel

in properly marked containers. DO NOT SMOKE.

a.

Remove plunger (5) and coat with clean diesel fuel oil.

b.

Install injector plunger extension tool on plunger (5).

c.

Hold injector adapter (3) in a vertical position with cup down and allow plunger to drip a few drops of oil into

the cup.

d.

Insert plunger (5) about 0.5 inch (12.7 mm) into barrel.

e.

Push plunger (5) in with palm of hand to seat plunger in cup, and rotate 90 degrees while holding plunger

against cup seat.

f.

Hold injector adapter (3) with cup up and lift quickly. If plunger (5) slides out, alignment is correct.

g.

If plunger (5) does not slide, try test again

after coating plunger tip with diesel fuel oil. If plunger

still does not slide out, injector must be replaced.

9.

Install inner spring (8), outer spring (9),

spring retainer (10), and plunger (5) into

injector adapter (3).

10.

Install injector plunger link (11), tappet (12),

and link (13) with retainer clip (14) into injector adapt-

er (3).

11.

Install injector stop screw (15) and locknut (16)

on injector adapter (3).

12.

Install filter screen (17) and screen retainer

(18) into injector adapter (3).

13.

Test and adjust injectors in accordance with

paragraph 3-35.

14.

Install injectors in accordance with paragraph 3-35.

4-87