TM 10-4320-307-24

2-53

ROCKER LEVER COVER ASSEMBLY REPAIR, / REPLACE.

This task covers: a . Removal b . Cleaning/Inspection/Repair c . Installation

INITIAL SETUP

Tools

Equipment

Tool kit, general mechanic's (Item 1, Appendix B)

Condition

Torque wrench (Item 2, Appendix B)

Reference

Condition Description

Material/Parts

Paragraph

Aftercooler air crossover

Gaskets

2-47

connection removed

Manual References

General Safety Instructions

TM 10-4320-307-10

Well ventilated area required for cleaning and testing.

REMOVAL:

1.

Remove two clamps and plain hose from crankcase breather assembly.

2.

Remove five capscrews and washers from each rocker lever cover.

3 . Remove covers.

CLEANING/INSPECTION/REPAIR:

1.

Remove crankcase breather and oil filler cap.

2.

Remove all gaskets

Live steam used for cleaning shall not exceed 100 psi (690 kPa) . During steam cleaning

operations, adequate ventilation, natural or forced, should be provided. Do not direct live steam

against skin.

Death or serious injury could occur if compressed air is directed against the skin. Do not use

compressed air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11

kgcm2) or less . When working with compressed air always use chip guards, eye protection, and

other personal protection equipment.

3.

Steam clean covers and dry with compressed air.

NOTE

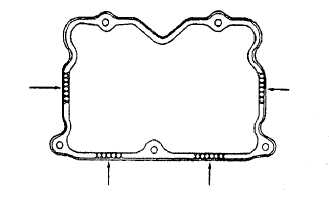

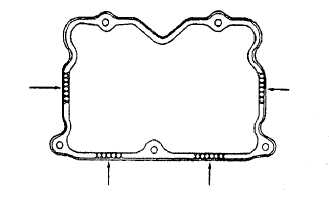

Stamped

steel

valve

covers

are

designed

and

manufactured with a 0.030-inch (0.75 mm) bow located

in the shaded areas as shown to provide better sealing

qualities . This built-in bow on the valve covers must

not be mistaken for warpage . Also, do not attempt to

increase or remove the bow from the sealing surface.

4 . Inspect each cover for cracks or damage.

NOTE

Repair of rocker lever assembly components is limited to the replacement of damaged

or faulty parts.

2-218