Table 4-1. Organizational Preventive Maintenance Checks and Services - (Continued)

W -Weekly

Q- Quarterly

M -Monthly

S- Semiannually

Interval

Item

Item

To Be

No. W M Q S

Inspected

Procedures

5

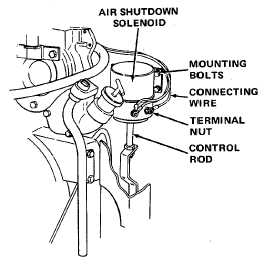

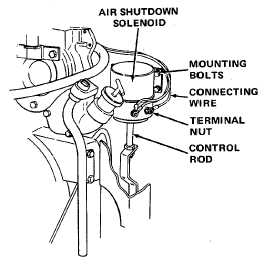

· Air Shutdown

Inspect solenoid for proper operation and for exterior

Solenoid

damage, broken or loose connecting wires, loose terminal

nuts, or broken insulation.

Inspect control rod for bends or other damage. Also inspect

other solenoid linkage components for exterior damage.

Check operation of air shutdown solenoid as follows:

WARNING

Exposure to exhaust gases produces symptoms of

headache, dizziness, loss of muscular control,

drowsiness, or coma. Brain damage or death can

result from severe exposure.

Fumes from engines become concentrated with

poor ventilation.

1. Operate engine in a ventilated area only.

2. Ventilate personnel compartments when

idling engine.

3. While running vehicles, be alert for fumes.

Keep compartments ventilated. If someone is

overcome, expose to fresh air; keep warm and

still; give artificial respiration if needed. Seek

medical attention. Administer oxygen, if

available.

GOOD VENTILATION IS THE BEST DEFENSE

AGAINST EXHAUST POISONING.

a. Start engine. Allow it to warm up for 1 minute.

4-15