TM 10-4320-344-24

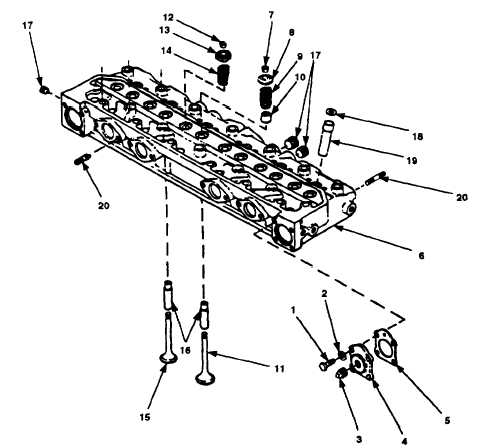

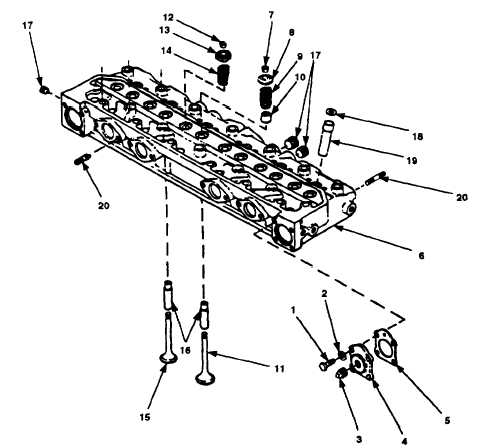

4.4.1 Cylinder Head Assembly.

Intake Valve, and Exhaust Valve Maintenance. Model 609-A. (Continued)

Figure 4-1.

Cylinder Head Assembly Disassembly, Model 609-A.

4.4.1.2 Repair.

a.

Clean valve stem guides (16) by running a valve cleaner and wire brush through

the valve stem guides (16).

b .

Using a straight edge and a 0.005 inch (1.2700 mm) feeler gauger check surface

of cylinder head (6) for warpage.

Also, inspect surface of cylinder head (6)

for cracks, erosion, pits, burrs, scratches, or blemishes.

Do not use cleaning solvent without proper ventilation and clothing.

Do not

smoke or use near open flame or excessive heat.

Dry cleaning solvent is

potentially dangerous to personnel and property.

Clean parts in a well-

ventilated area.

Avoid inhalation of solvent fumes.

Wear goggles and rubber

gloves to protect eyes and skin.

Wash exposed skin thoroughly.

Failure to

obey this warning may result in personal injury or death.

c .

Inspect cylinder head (6) for free water flow.

I f r e s t r i c t i o n i s e v i d e nt

remove plugs (17), six flat washers (18),

and nozzle sleeves (19).

Clean

water jackets by submerging cylinder head (6) in heated cleaning solution.

d.

Inspect cylinder head (6) for loose or damaged nozzle sleeves (19), studs

(20), and pitted or shouldered intake and exhaust valve seats.

4-4