TM 10-4320-310-14

3-2. CHECKING ENGINE OIL (Continued)

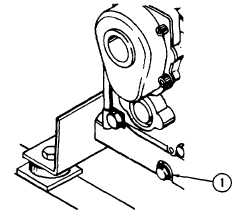

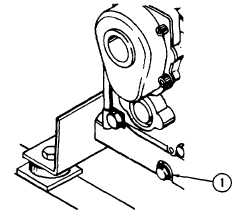

d. If oil coating extends above top mark, loosen drain plug (1) enough to lower oil level to top mark on

dipstick, then tighten drain plug (1) securely.

3-3. CHANGING ENGINE OIL

Change engine oil after every 150 hours of operation or

every six months as follows:

a. Remove drain plug (1) and drain oil from engine

crankcase. Reinstall drain plug.

b. Remove oil cap and add 1.1 quarts of oil of

proper viscosity required by ambient temperature.

c. Check oil level with dipstick. Reinstall oil cap.

d. Check that oil cap is tightly closed.

Section II. TROUBLESHOOTING PROCEDURES

3-4. TROUBLESHOOTING

a. Table 3-1 lists common malfunctions which you may find during operation or maintenance of the

centrifugal pump unit or its components. You should perform the tests/inspections and corrective actions in the

order listed.

b. This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective actions. If

a malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

c. Only those malfunctions within the scope of operator maintenance are listed.

3-5. SYMPTOM INDEX

Refer to the Symptom Index below. Locate the malfunction which is the same, or most nearly the same, as the

trouble you are having with the centrifugal pump unit. The Symptom Index lists the first page of the

troubleshooting information for that malfunction. Follow the steps one by one, and perform the corrective actions

listed.

Symptom Index

Malfunction

Number

Description

Page

1

Engine hard to crank

3-3

2

Engine fails to crank

3-3

3

Engine cranks but fails to start

3-3

4

Uneven running or frequent stalling

3-4

5

Lack of power

3-4

6

Dense smoke from exhaust after warm-up

3-5

7

Unit overheats (erratic operation, lack of power)

3-5

3-2