TM 10-4320-309-14

TM 4320-14/1

Piston ring breakage may occur if rings are opened more

than necessary when installing. Never stretch piston rings

more than necessary.

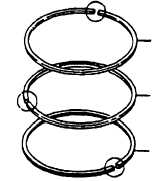

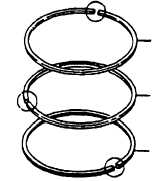

1st compression ring

2nd compression ring

Oil ring

Figure 5-38. Piston Ring Installation

c.

Use the piston ring remover tool to install piston rings. Install oil ring, 2nd compression ring, and 1st

compression ring in order.

d.

Make sure each piston ring gap is 120 degrees.

e.

Make sure the piston rings move smoothly.

f.

Apply liberal amount of lubricating oil to the outer surface of the piston and inner surface of the cylinder

sleeve.

g.

Align the identification mark DM in the piston head with the matching mark on the connecting rod.

h.

Make sure the main bearing is in the proper position.

i.

Install crank pin bearing insert (refer to 9, Figure 5-31) into connecting rod (refer to 2, Figure 5-31).

5-38