TM 10-4320-226-14

6.6.4 Engine Maintenance.

(continued)

e.

f.

g.

h.

Start by tightening middle bearing cap and those on either

side, finish with bearing caps at ends.

The crankshaft

must be able to rotate freely.

Install bearing caps (7) and (6), with their identification number

corresponding to and in same direction as that stamped on crankcase.

Install

washers (5) and bolts (4).

Torque in accordance with appendix G.

Install pistons (3).

Install connecting rod caps (2) and connecting rod bolts (1).

Torque in

accordance to appendix G.

Assembly flywheel assembly as follows:

(1) If ring gear (figure 6-9, 12) has been removed, heat new ring gear to a

temperature of 248° F (120°C) and position it on flywheel (11) and tap it

into position so it seats against shoulder.

(2) Install flywheel (11) with bolts (10). Torque in accordance with

appendix G.

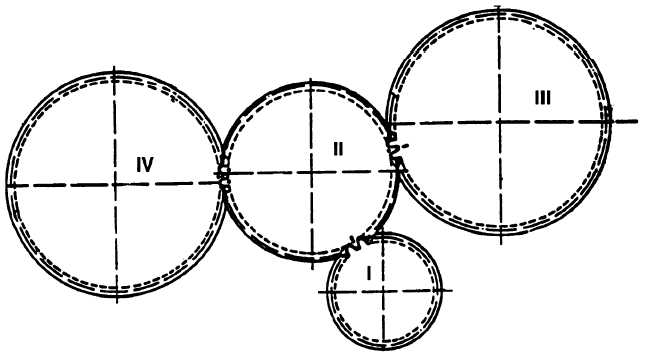

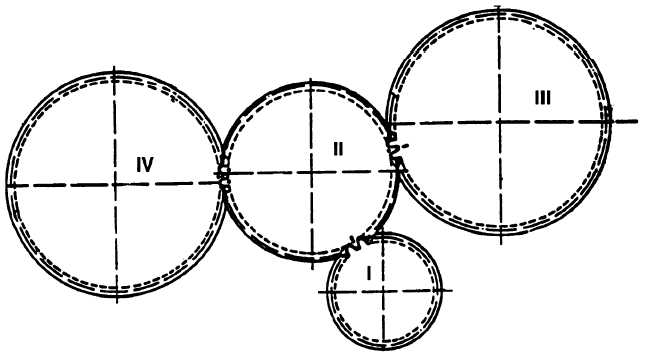

I - CRANKSHAFTGEAR

II - IDLERGEAR

III - CAMSHAFTGEAR

IV - INJECTION PUMP GEAR

Figure 6-15.

Timing Gears Layout with Match Marks.

6-31