TM 10-4320-226-14

6.6.4 Engine Maintenance.

(continued)

6.6.4.2 Repair.

a.

Inspect and repair crankshaft as follows:

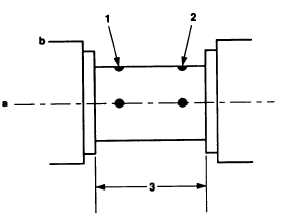

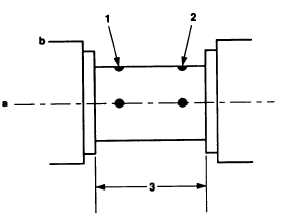

(1) Using micrometer, measure all journal diameters at points

(figure 6-12, 1, 2, and 3), in the vertical and horizontal, as indicated by

"a" and "b".

Figure 6-12.

Checking Crankshaft Journals.

(2) Note measurements and compare with table 6-2.

Table 6-2 Crankshaft Measuraments.

(3) Wear limit for ovality is 0.0008 inch (0.01 mm).

(4) Using a micrometer, check other journals for out-of-round.

(5) Replace crankshaft if it is defective.

b.

Measure camshaft bearing journal outside diameter.

Record journal diameter.

c.

Measure inside diameter of bearing.

Subtract journal diameter from its

bearing inside diameter.

Replace bearing if difference (clearance) is more

than 0.0079 inch (0.20 mm).

Use removal and installation tool to replace bearing.

Bearing is removed by

pressing out in direction of flywheel and installed by aligning oil holes

with crankcase holes and pressing in from front side.

6-27