TM 5-4320-275-13 & P

4-10. GENERAL INSTRUCTIONS

Most maintenance instructions in this section will list resources required, personnel required, and equipment condition for

the start of the procedure. Note the following:

Resources required are not listed unless they apply to the procedure.

Personnel required are listed only if the task requires more than one. If PERSONNEL is not listed, it means one

person can do the task.

The normal standard equipment condition to start a maintenance task is engine stopped and cutoff switch off.

EQUIPMENT CONDITION is not listed unless some other condition is required besides the power being off.

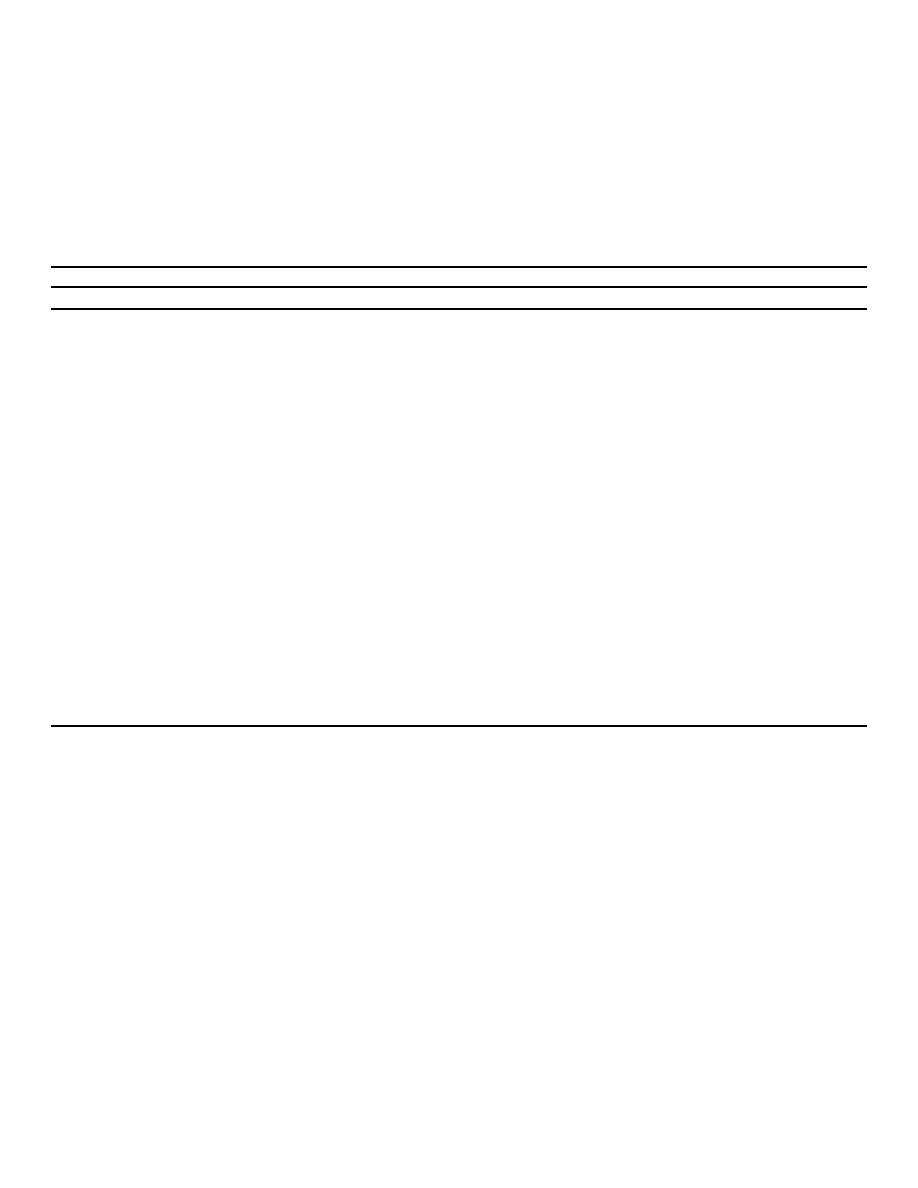

4-11. PUMP ASSEMBLY INSPECTION

Component

Acceptable

Repairable

Not Repairable

Engine

Attaching screws tight.

Loose screws.

Stripped screw holes.

Fuel filter

Clean.

Dirty.

Stripped threads or

broken.

Fuel tank

No leaks.

Replace tank.

None.

Fuel line

No leaks.

Tighten fuel lines.

Leak in fuel line.

Wheel assembly

Tight. No air leaks.

Replace leaking tires.

None.

Frame assembly

No cracks.

None.

---

Data plates

Legible. Tight.

Replace.

---

Accumulator

No leaks.

Replace gasket.

Crack in accumulator.

Pipe plug

Tight. No leaks.

Tighten pipe plug.

---

Check valve

No leaks. Operable.

Replace valve assembly.

None.

assembly

Bowl pipe plug

Tight. No leaks.

Tighten pipe plug.

---

Diaphragm

No leaks.

Replace diaphragm.

None.

Discharge port

No leaks.

Replace gasket.

Crack in discharge port.

Clamp assembly

Tight.

Loose nuts.

Stripped threads on

studs.

Connecting rod

Tight.

Loose shoulder bolt.

Bent or cracked rod.

assembly

Coupling

Minimal backlash.

Replace coupling.

None.

Gear reducer

No binding.

Replace gear reducer.

None.

4-24