TM 5-4320-275-13 & P

2-4. INITIAL ADJUSTMENTS

Inspect pump assembly and engine for loose or missing hardware, corrosion, or obvious damage. Report any problems

to organizational maintenance.

2-5. OPERATING PROCEDURE

a.

Selection and Preparation of Pump Site.

(1) Locate the pump on a level surface as close to the liquid supply as possible.

(2) Block the wheels of the pump assembly to prevent the pump from shifting during operation.

(3) When connecting suction hose to pump assembly, the suction lift of the pump must not exceed 25 feet

(7.62 m).

b.

Hose Installation.

NOTE

Use the shortest possible length of suction hose. Suction hose exceeding 20 feet (6.09 m) will

reduce the pump capacity.

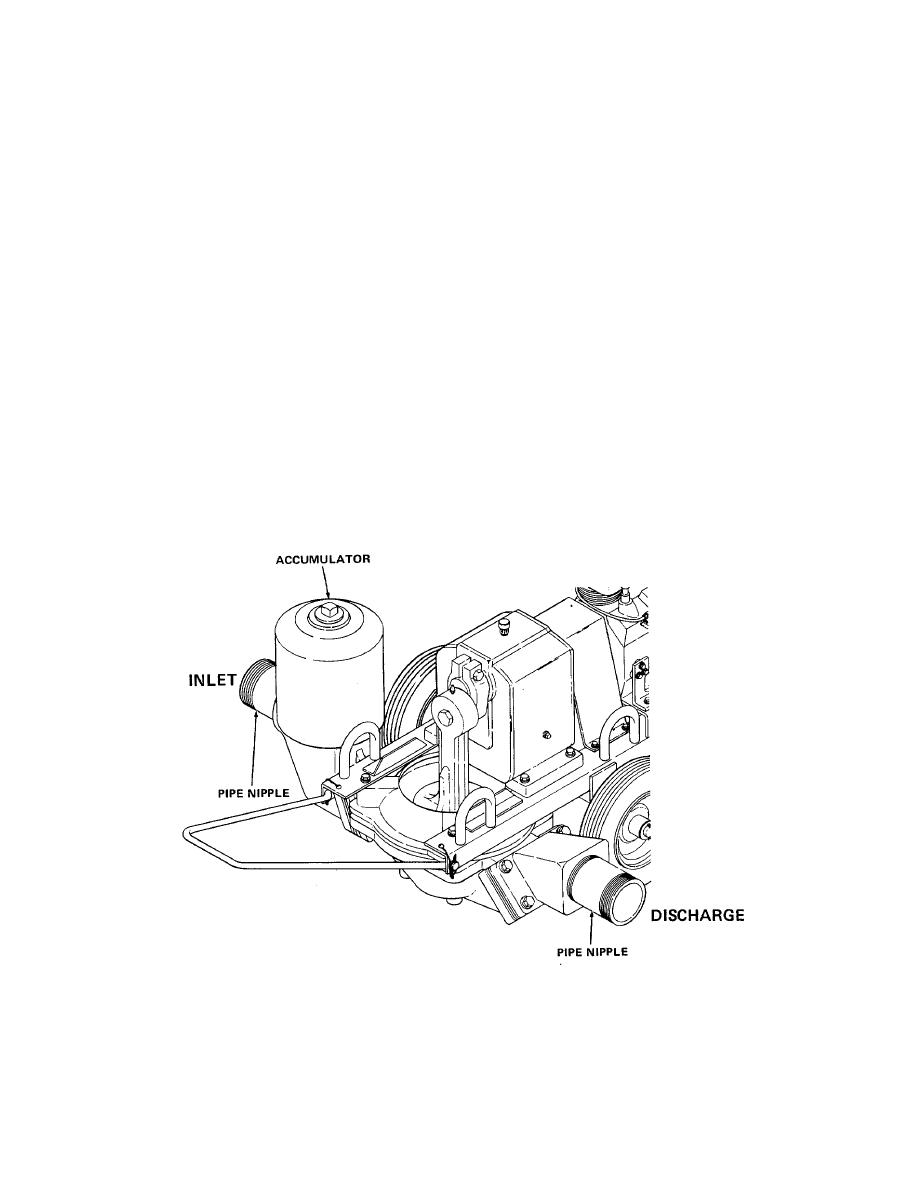

(1) Connect the suction hose to the accumulator pipe nipple. Use thread sealant on threaded connections.

Tighten the suction hose with a spanner wrench NSN 5120-00-277-9077.

(2) If more than one length of hose is required, add additional lengths to end of first hose attached to pump.

2-6