TM 10-4320-309-14

TM 4320-14/1

REMOVAL:

Keep exhaust and intake tappets separate. They may fall

down when pulling out the camshaft and may be confused.

a.

Check the location of the timing marks on all gears.

b.

Lay engine down on the flywheel side to prevent tappets from falling out.

c.

Pull out the camshaft.

INSPECTION/REPLACEMENT

a.

b.

c.

d.

e.

f.

g.

Clean camshaft with diesel fuel.

Inspect all components for damage or excessive wear. Replace any

worn.

components

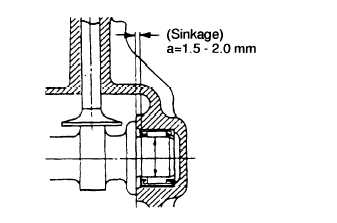

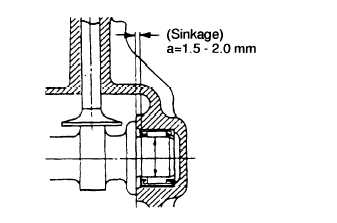

Figure 5-17. Recess of Needle Bearing

Check the clearance at the thrust of the camshaft (cylinder block side). The camshaft bearing has been

press-fitted into the cylinder block. Maintain the recess between the press-fitted bearing face and the

thrust surface of cylinder block at 0.059-0.079 inch (1.5-2.0 mm).

Check the OD of the camshaft on the needle bearing/cylinder block side. OD of camshaft must be at

least

0.587 inches (14.92 mm). Replace camshaft if OD is under the wear limit.

Check the OD of the camshaft on the ball bearing/crankcase cover side. OD of camshaft must be at

least 0.981 inch (24.90 mm). Replace camshaft if OD is under the wear limit.

Check that the ID of the ball bearing on the crankcase cover side is greater than 0.984 inch (24.98

mm). Replace ball bearing if it exceeds the wear limit or is damaged.

Check the condition of the tappet contact point. The tappet is offset with regard to the cam center and

rotated during operation to prevent excess wear. Replace the tappet if it is badly worn or contacts the

cam improperly.

severely damaged or

5-20