TM 10-4320-307-24

2-43

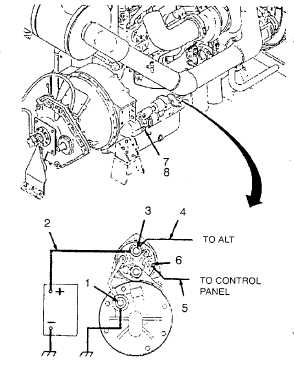

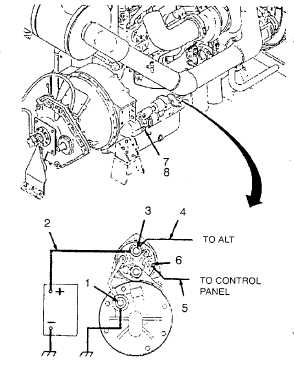

STARTER ASSEMBLY TEST/REPLACE (CONT).

2.

Remove starter cables as follows:

a.

Remove negative cable from starter post (1).

b.

Remove positive cable (2) from positive starter post (3).

c.

Remove starter switch terminal wire (4) from positive

starter post (3).

d.

Remove magnetic switch terminal wire (5) from starter

terminal (6).

3.

Remove three bolts (7) and washers (8) and remove starter

assembly from engine.

TEST/INSPECTION:

CAUTION

A cranking motor is designed for intermittent duty only, and should never be

operated for more than 30 seconds at a time. After 30 seconds, the cranking must be

stopped for at least 2 minutes to allow the motor to cool.

1.

Check armature for free rotation of pinion gear.

NOTE

Tight bearing, a bent armature shaft, or a loose pole shoe screw will cause the armature to

not turn freely. If the armature does not turn freely, replace starter and notify direct support

maintenance. If the armature does turn freely, proceed to step 2 for a no-load test.

2.

Perform a no-load test as follows:

NOTE

The no-load test may point to specific defects which can be verified with tests when

disassembled. Also, the no-load test can identify open or shorted fields, which are difficult to

check when disassembled. The no-load test also can be used to indicate normal operation on a

repaired motor before installation.

2-172